Shelf-life and post-harvest quality of tomato (Lycopesicon esculentum Mill.) varieties to different packaging materials at Mersa, North Wollo, Ethiopia

Published 2024-01-18

How to Cite

Copyright (c) 2023 Seid Hussen Muhie, Solomon Worku, Biruk Masrie

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

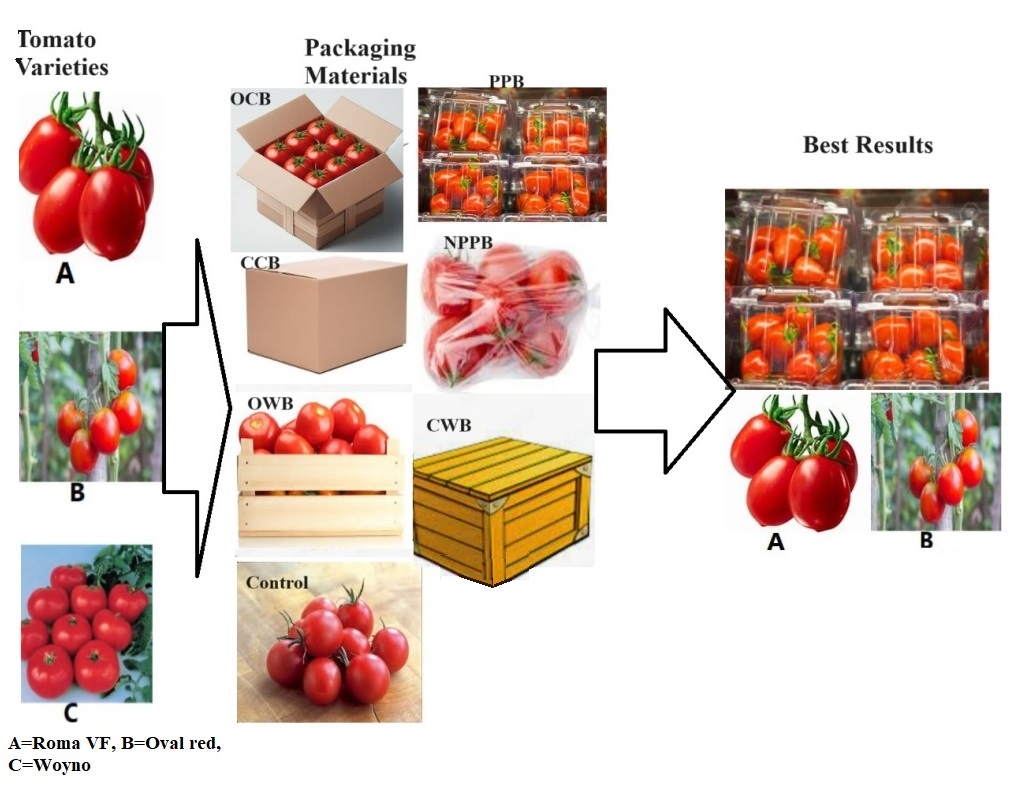

Tomato (Lycopersicon esculentum Mill.) has a short shelf life at ambient conditions and is a highly perishable crop. Extreme post-harvest losses occur as a result of the wrong packaging materials. However, by employing the right packing materials, tomato varietals can have longer shelf lives. Globally rising fresh tomato demand has forced the development of essential mechanisms, including packaging materials, to improve shelf life. The current study was initiated to evaluate the quality and shelf-life of tomato varieties in response to packaging materials at Mersa, North Wollo, Ethiopia, during 2021 cropping season. Three replications of a completely randomized design were used to test three tomato varieties (Roma VF, Oval red and Woyno) and seven packing materials [closed carton (CC), open carton (OC), closed wooden box (CWB), open wooden box (OWB), perforated polyethylene bag (PPB), non-perforated polyethylene bag (NPPB) and control (C)] at room temperature (20-22°C). According to the findings, there is a significant (P<0.05) interaction effect between packaging materials and varieties on a number of parameters, including physiological weight loss, decay percentage, disease incidence, total soluble solids (TSS), tomato fruit PH, juice color score, overall acceptability, marketability percentage, and shelf life. Non-perforated polyethylene plastic experienced the highest physiological weight losses of 79.88% and 79.63% after 18 days of storage. Roma VF variety showed the greatest weight loss. In addition, PPB showed the lowest decay percentage (20%) and maximum marketability (20%) during the 18th day of storage. At the end of storage, NPPB with Roma VF and Woyno varieties had a substantially (100%) larger decay loss of tomato fruits. NPPB has been linked to the highest disease incidence (20%). Roma VF and Oval red recorded the highest pH tomato fruit’s color and overall acceptability score on PPB. It can, thus, be concluded that packaging of tomato fruits in PPB can extend shelf-life with better-quality of the produce. However, to develop plausible recommendation, the study should be repeated in multi-location with more packaging methods and varieties over seasons.